- 0531-87887788

来源:http://www.jndclyyxgs.com/ 发布时间:2022-06-30

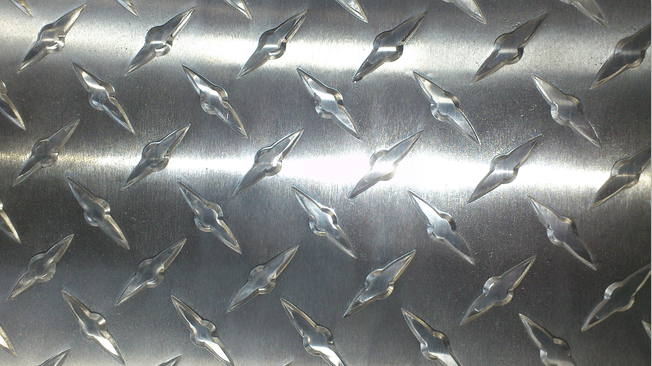

在合金铝板的整个生产过程中,不可避免地会遇到许多产品问题。一些产品质量问题是由于在整个生产过程中工作人员的粗心大意而引起的,而一些产品质量问题是由于在应用的中后期阶段实际操作不当而引起的。那么合金铝板上白点和油污怎么进行处理呢?

In the whole production process of aluminum alloy plate, many product problems will inevitably be encountered. Some product quality problems are caused by the carelessness of the staff in the whole production process, while some product quality problems are caused by improper operation in the middle and later stages of application. How to deal with the white spots and oil stains on the alloy aluminum plate?

合金铝板上白点

White spot on alloy aluminum plate

对于外观要求严格的铝板,如何防止铝板外表面出现白点,使产品光滑光亮,不仅与加工技术有关,而且与后来的外观加工技术息息相关。

For the aluminum plate with strict appearance requirements, how to prevent white spots on the outer surface of the aluminum plate and make the product smooth and bright is not only related to the processing technology, but also closely related to the subsequent appearance processing technology.

在对大型铝合金产品进行阳极氧化处理时,加工完成后表面会出现白点,尤其是氧化铝板更为显着。让我们分析这种情况下的因素。实际上,主要因素很简单:铝板被氧化后,冲刷不完全,导致镗孔后表面上出现白点。解决方法是加强氧化后的精练,并尝试使用水枪将其完全冲洗。同时,在将来,您应注意保持外观,并尝试使本产品远离其他产品并自然干燥。

When large aluminum alloy products are anodized, white spots will appear on the surface after processing, especially on the aluminum oxide plate. Let's analyze the factors in this case. In fact, the main factor is very simple: after the aluminum plate is oxidized, the erosion is not complete, resulting in white spots on the surface after boring. The solution is to strengthen the scouring after oxidation and try to rinse it completely with a water gun. At the same time, in the future, you should pay attention to maintaining the appearance and try to keep this product away from other products and dry naturally.

换句话说,如果要更好地控制铝板上白点的出现,不仅要在产品加工过程中注意产品的外观,还要在外观加工中注意预防,并规范严格的加工工艺和加工工艺,防止白斑的形成。干净的白色斑点,酸洗和碱洗都可以,但是您需要控制浓度,或喷涂油漆以阻止铝和氧气被触摸。

In other words, if we want to better control the appearance of white spots on the aluminum plate, we should not only pay attention to the appearance of the product during the product processing, but also pay attention to prevention during the appearance processing, and standardize the strict processing technology and processing technology to prevent the formation of white spots. Clean white spots, pickling and alkaline washing are OK, but you need to control the concentration, or spray paint to prevent aluminum and oxygen from being touched.

合金铝板上油污

Oil stain on alloy aluminum plate

在铝板的生产中,可以避免实际操作和机械设备的使用。铝板存在许多常见的产品质量问题,油渍问题是常见的质量损失之一。油渍并不意味着铝板在生产后会被污染。只是铝板冷轧之后,铝板制造商在铝头的表面上放了太多的油,并且除了轧制的油膜外还添加了剩余的油脂。在产品咨询和批量生产的中后期,您会发现这种脂肪在外面肉眼可见。

In the production of aluminum plate, the actual operation and the use of mechanical equipment can be avoided. Aluminum plate has many common product quality problems, and oil stain is one of the common quality losses. Oil stains do not mean that the aluminum plate will be contaminated after production. Only after the cold rolling of the aluminum sheet, the aluminum sheet manufacturer put too much oil on the surface of the aluminum head, and added the remaining grease in addition to the rolled oil film. In the middle and late stages of product consultation and mass production, you will find that this fat is visible to the naked eye.

许多油脂主要散布在挤出机入口和出口的顶部和底部或辊的颈部。飞溅后,它会滴在盒子的表面上,然后由于挤出机测厚仪的漏油而在挤出机滚筒清洁器中被发现是异常情况,并且这种油的成分很杂而且很脏。由铝板制造商生产的铝板表面上的这种油渍会严重损害合金铝板的外观。

A lot of grease is mainly distributed at the top and bottom of the extruder inlet and outlet or at the neck of the roll. After splashing, it will drop on the surface of the box, and then it is found to be an abnormal condition in the extruder drum cleaner due to the oil leakage of the extruder thickness gauge, and the composition of this oil is very miscellaneous and dirty. Such oil stains on the surface of aluminum plates produced by aluminum plate manufacturers will seriously damage the appearance of alloy aluminum plates.

难道说没有办法在出产时就避免这种产品质量问题吗?自然并不是,实际上铝板生产厂家可以在出产铝板前就对出产机器设备开展综合严格查询。假如在机械设备中本身就会有很多油渍,

Is there no way to avoid this product quality problem at the time of production? Of course not. In fact, aluminum plate manufacturers can carry out comprehensive and strict inquiry on production machinery and equipment before producing aluminum plates. If there are many oil stains in the mechanical equipment,

应该立即将其清理干净,并出于某种原因进行适当处理。同时,我们还应清理所生产产品的表面。如果铝板制造商刚开始时有不干净的油渍,则将立即报销产品。如果将油性产品放到仓库或销售市场中,则事后控制产品质量总是比较困难,并且存在许多无法解决的售后服务问题。

It should be cleaned immediately and properly disposed of for some reason. At the same time, we should also clean the surface of the products we produce. If the aluminum plate manufacturer has dirty oil stains at the beginning, the product will be reimbursed immediately. If oily products are put into the warehouse or sales market, it is always difficult to control the product quality afterwards, and there are many unsolvable after-sales service problems.

铝板也很容易刮擦。实际上,有很多原因会导致铝板刮擦,刮擦或敲打。这可能是由于辊子和导辊表面的划痕引起的。铝板上的划痕通常是凹槽状的疤痕,当它出现在外部时有时会消失或持续。

Aluminum plates are also easy to scratch. In fact, there are many reasons for aluminum scraping, scraping or knocking. This may be caused by scratches on the surface of the rollers and guide rollers. Scratches on aluminum plates are usually grooved scars that sometimes disappear or persist when they appear on the outside.

以上就是问题解答的相关内容了,希望能够帮助到大家,如对这一问题还存在任何疑问,都欢迎关注我们网站http://www.jndclyyxgs.com并咨询我们的工作人员,将竭诚为您服务。

The above is the relevant content of the question answer. I hope it can help you. If you still have any questions about this problem, you are welcome to follow our website http://www.jndclyyxgs.com And consult our staff, will serve you wholeheartedly.