- 0531-87887788

来源:http://www.jndclyyxgs.com/ 发布时间:2021-03-04

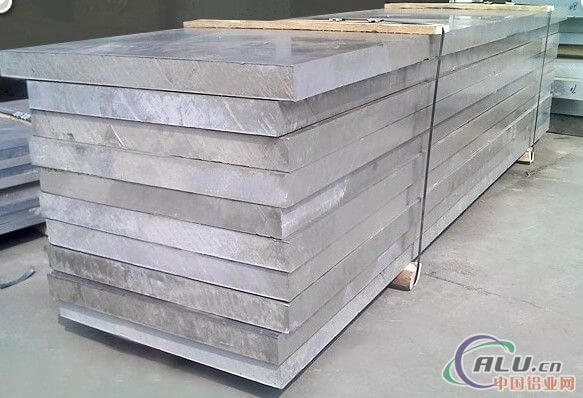

5052铝板可用作装饰材料,其常见形式是拉丝铝板。 购买5052铝板时,如何检查拉丝铝板的质量? 是检查徽标。 通常,我们购买的常规5052拉丝铝板都标记有产品的标准代码和许可证。 第二是检查氧化膜的厚度。 这是使用的涡流厚度测量仪来检测5052拉丝铝板。

5052 aluminum plate can be used as decoration material, and its common form is wire drawing aluminum plate. When purchasing 5052 aluminum plate, how to check the quality of drawn aluminum plate? The first is to check the logo. In general, the standard code and license of the product are marked on the conventional 5052 wire drawing aluminum plate we buy. The second is to check the thickness of the oxide film. This is the use of professional eddy current thickness measuring instrument to detect 5052 drawing aluminum plate.

当生产5052铝板时,如果客户需要不同的要求,例如弯曲要求,产品用途等,那么在生产过程中需要考虑许多因素,例如退火温度,退火时间,铝板厚度等。 您此时操作不当,会对5052铝板的性能产生很大影响,因此我们的5052铝板制造商在生产时必须更加注意它。

When producing 5052 aluminum plate, if customers need different requirements, such as bending requirements, product use, etc., many factors need to be considered in the production process, such as annealing temperature, annealing time, aluminum plate thickness, etc. Your improper operation at this time will have a great impact on the performance of 5052 aluminum plate, so our 5052 aluminum plate manufacturers must pay more attention to it.

,我们需要知道5052压纹铝板的平整度与模具的其余部分有很大关系。 如果模具的流量不均匀,则会导致平面度误差。 通常,可以通过调节流量来消除平面间隙差。 5052压纹铝板在初始生产中通常使用此方法。 一些模具修复可以一次解决平整度问题,而某些模具需要3次或更多次才能完全解决平整度问题。 这不仅与模具本身有关,而且与铝皮和维护有关。 工人与他们的技术水平也有更大的关系。

First of all, we need to know that the flatness of 5052 embossed aluminum plate has a lot to do with the rest of the mold. If the flow of the mold is not uniform, it will lead to flatness error. Generally, the plane gap difference can be eliminated by adjusting the flow rate. 5052 embossed aluminum plate usually uses this method in the initial production. Some molds can be repaired once to solve the flatness problem, while some molds need three or more times to completely solve the flatness problem. This is not only related to the mold itself, but also related to the aluminum sheet and maintenance. Workers also have more to do with their skills.

5052铝板氧化产生黑色长丝的原因很多。 在生产过程中,轧制机油会滴在铝板的表面上。 由于过大的压力或过大的张力,5052铝板的表面可能会有凹痕。 这些深色标记将变得越来越稀,形成深色线或黑线,有时不清楚是油还是痕迹,甚至表面上没有色差,但氧化后显然不能用作 装饰铝板。

There are many reasons for black filament produced by 5052 aluminum plate oxidation. In the production process, rolling oil will drop on the surface of aluminum plate. The surface of 5052 aluminum plate may have dents due to excessive pressure or tension. These dark marks will become thinner and thinner, forming dark lines or black lines. Sometimes it is not clear whether it is oil or traces, or even there is no color difference on the surface. However, after oxidation, it can not be used as decorative aluminum plate.

另一件事是检查表面质量。 除了5052拉丝铝板的清洁度外,我国还需要能够看到更多。 例如,我们应该检查是否出现了5052拉丝铝板。 有裂纹或无腐蚀迹象。 这些问题只是发现的,需要仔细观察。

Another thing is to check the surface quality. In addition to the cleanliness of 5052 aluminum plate, China needs to be able to see more. For example, we should check whether there is 5052 wire drawing aluminum plate. There are cracks or no signs of corrosion. These problems are only discovered by China and need to be carefully observed.