- 0531-87887788

来源:http://www.jndclyyxgs.com/ 发布时间:2019-03-30

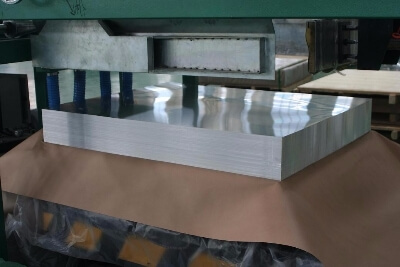

铝板厂家如何区别拉丝铝板和氧化铝板?对于初次接触铝板的朋友来说,如何区分铝板的类别是一个不小的挑战,作为铝板生产厂家为您排忧解难是我们义不容辞的责任,就较常见的拉丝铝板和氧化铝版给您详细介绍下。

How does aluminium plate manufacturer distinguish wire drawing aluminium plate from alumina plate? For the first time contact with aluminium plate friends, how to distinguish the type of aluminium plate is a big challenge. As an aluminium plate manufacturer, it is our duty to help you solve the problems. The most common drawing aluminium plate and alumina plate are introduced in detail.

拉丝铝板:反复用砂纸将铝板刮出线条的制造过程,其工艺主要流程分为脱酯、沙磨机、水洗3个部分。在铝板拉丝制程中,阳极处理之后的特殊的皮膜技术,可以使铝板表面生成一种含有该金属成分的皮膜层,清晰显现每一根细微丝痕,从而使金属哑光中泛出细密的发丝光泽。

Wire drawing aluminium sheet: The manufacturing process of scraping aluminium sheet out of line repeatedly with sandpaper. Its main process is divided into three parts: deesterification, sand mill and water washing. In the process of drawing aluminium sheet, the special skin film technology after anodic treatment can make the surface of aluminium sheet produce a kind of skin film containing this metal component, which can clearly show each fine filament mark, and thus make the metal glossy and lustrous.

拉丝铝板的系列很多,不同系列的具有自己独特的铝板属性,具体表现在他的拉丝效果、抗腐蚀性、抗污性,那么这些性能的具备当然需要有时候在拉丝的过程中加入部分氧化性,但是这不等同于拉丝铝板就是氧化铝板,这样是不科学的。

There are many series of wire drawing aluminium sheets. Different series have their own unique properties of aluminium sheets, which are embodied in their drawing effect, corrosion resistance and contamination resistance. It is of course necessary to add some oxidation in the process of wire drawing, but this is not the same as that of aluminium sheet, which is not scientific.

氧化铝板:将铝板置于相应电解液(如硫酸、铬酸、草酸等)中作为阳极,在特定条件和外加电流作用下,进行电解而形成的铝板。阳极的铝板氧化,表面上形成氧化铝薄层,其厚度为5~20微米,硬质阳极氧化膜可达60~200微米。

Alumina plate: Aluminum plate is formed by electrolysis of aluminum plate in corresponding electrolyte (such as sulphuric acid, chromic acid, oxalic acid, etc.) as an anode under specific conditions and applied current. A thin layer of alumina is formed on the surface of the anode when the aluminium plate is oxidized. Its thickness is 5-20 microns, and the hard anodic oxide film can reach 60-200 microns.

氧化铝板也同样有很多系列,但是他们都有一个共同特点就是表面都是具有氧化膜的铝板,他的表面跟具有拉丝纹理的拉丝铝板有截然不同。

There are also many series of alumina sheets, but they all have a common feature that the surface is aluminium sheets with oxide film, and its surface is quite different from that of aluminium sheets with drawing texture.